Functional Modules

Pack+ ERP©

GENERAL INFORMATION

Pack+ ERP© is a software designed and developed solely and exclusively for the flexible packaging industry, which will allow you to optimize your processes, increase competitive advantages and profits more efficiently, reduce costs, increase control of your processes, and make timely decisions based on automatic notifications, indicators, statistics ethics and reports in real-time.

Pack+ ERP© is “Plug & Play”. Our solution understands the flexible packaging industry, its requirements, and restrictions, and therefore will not require customization efforts to start enjoying the power of Pack+ ERP©. If your company extrudes, prints, laminates, refines, and converts films, bags, and labels, Pack+ ERP© is the software designed for you. Regardless of whether your manufacturing plant is small, medium, or large, Pack+ ERP© will attend and will support all your needs from day one and will gradually adapt to the extent that your company is growing.

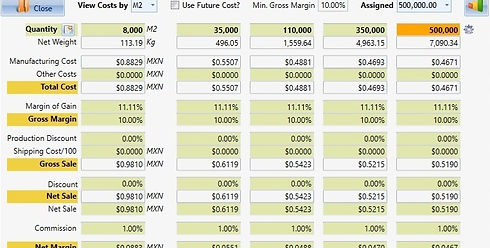

Product Definition and Cost Estimation

Pack+ ERP© will allow you to quote accurately and in a fast way products to be manufactured with an unlimited combination quantities and conditions. Starting from a product definition that can be generated in minutes, you can specify the dimensions of the bag or film, gauge, manufacturing process route, raw materials to use, scrap, time, labor, and overheads. The system provides the convenience of calculating the costs of a product to be sold and controlling profit margins with just a click, saving time and effort. Additionally, you can compare the profit margins with the latest quotes or sales orders issued for the same product, enabling you to make informed decisions. Given the above and many other benefits, Pack+ ERP© becomes the only solution that naturally understands the manufacturing processes, the management of raw materials, times, and overheads involved, and therefore can accurately generate theoretical costs and times involved in the manufacturing of any product.

Quotes and Sales Orders

Pack+ ERP© has a powerful search engine that will allow you to find the complete history of any previously quoted or ordered product. You will always be able to control and know in detail the status of quotes and orders that are active, in progress, completed, closed, or canceled.

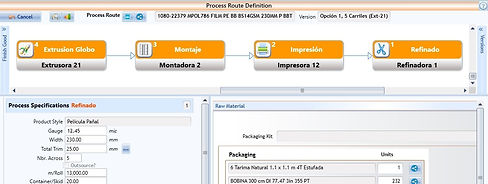

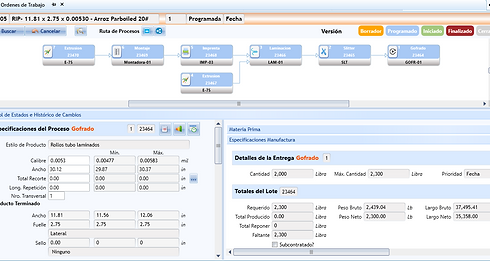

Production Order

Manufacturing orders are generated automatically from the product definition to save time and minimize the risk of errors. All instructions, notes, and observations are automatically integrated into the manufacturing orders to ensure that the product is manufactured, packaged, and shipped according to the customer's conditions and specifications. In this module you can plan first-hand how the product will be manufactured, allowing you to establish whether each process is manufactured 100% through sub-runs, or a combination of the two. So, for example: for a product with two deliveries, it could be defined that 100% of the material required for the order is extruded, but the printing, laminating, and bagging are processed in individual runs according to the quantities specified for each release.

Scheduling

It allows you to generate, control, and monitor the manufacturing plant calendar in real-time and in a graphical and friendly way. The multi-speed machine support allows the system to automatically calculate the required or remaining times to complete each manufacturing run based on the assigned machines, the type of product, its characteristics, and the status or progress of the previous processes. Additionally, it is the only one of its kind capable of generating the planning of raw material requirements for the entire plant, combining them with available inventory, active purchase orders, receipts of material in progress, availability, committed load, and machine preventive maintenance scheduling.

Production Plant

The production plant module is designed based on flexible packaging and conversion; Therefore, it provides all the necessary tools so that production plant personnel can carry out day-to-day tasks without requiring access to other applications. Multiple operators and machines can share a single workstation. With just a click, this system will allow the operator to consult work orders and their respective graphic aids. In seconds you can record production, waste, time, samples, variations in machine conditions, etc.

The system is designed to support the use of touch screens, printing and reading barcodes, reading scales, and connecting to different external devices for collecting and/or sending data.

Inventory

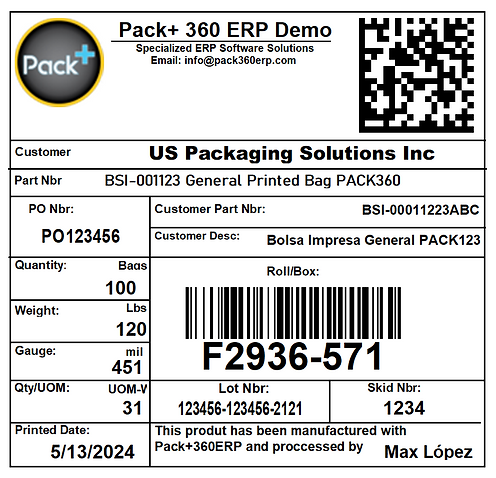

The Pack+© inventory module is designed to support the implementation of the best manufacturing practices in terms of inventory management, control, and treatment. It works under the concept of real-time; so all deliveries, departures, consumption, and any event are automatically reflected everywhere. The automatic assignment of unique codes for each inventory item allows you to control the life cycle of a particular item (a roll, a box, a pallet, etc.) at all times. The system has a traceability engine that collects all actions that affect the status, quantities, and location of any inventory item, allowing any item to be tracked from the moment it is received from the supplier, or produced until it is consumed, shipped, or dispatched.

Pack+© is integrated with the BarTender API, which is known as a top-level software in the world. Barcode templates designed in BarTender will automatically connect to Pack+© without requiring technical knowledge.

Purchases

Pack+ comprehensively includes the process of purchasing inventory items, from the material requirements made by other departments, the quality certification, control of complaints to suppliers, and to the release of the material as such. The system will allow you to purchase material in any unit of measure and receive it in the native unit of measure of the respective item.

Shipments

It allows you to automatically generate shipping orders based on the delivery schedule agreed with the client. The shipping process is designed based on a simple process flow that includes the shipping, warehouse, quality, and finance departments. As a shipment progresses between stations, the different documents and authorizations are automatically generated electronically, in such a way that all the physical documents that usually require a manual or semi-automatic process are eliminated.

Customer Claims

Pack+ includes a customer claims manager that allows you to register complaints and claims linked to a shipment and sales order. The system implements a process flow, in which the customer service, quality, warehouse, and finance departments intervene easily.

Integration API

Pack+ is designed and prepared to interact and share data virtually with any third-party system. All functionalities that affect inventories, costs, accounts receivable, accounts payable, and billing are natively integrated into the integration API, and from there they can be consulted manually, exported to files in different formats, and shared to third-party system in real-time

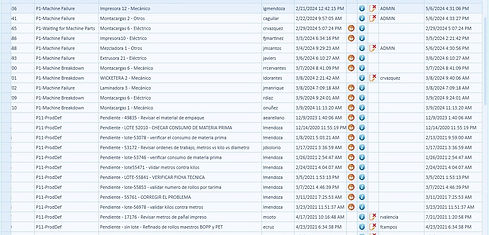

Task Flow Manager

The Pack+© task flow manager is a versatile, flexible, and easy-to-use tool that will allow you to implement, control, and maintain any flow of activities in the system without requiring major efforts. Pack+© keeps a complete record of all the events that occur during the life cycle of a process, allowing statistics and indicators to be generated with one click. The power of the task manager will allow your company to formalize, control, and measure the status of all requests, requirements, tasks, and news reports that typically occur between departments via email, phone calls, chats, or even verbally.